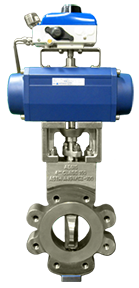

Aegis Flow Technologies

Specially designed for the Caustic Evaporation Process.

Specially designed for the Caustic Evaporation Process.

| CEV Valve | Standard Features |

| Application | Specically Designed for the Caustic Evaporation Process |

| Standards | 16.5, 16.34, MSS 25/55, API 609 |

| Size | 2"- 8" |

| Body Material | Nickel 200 |

| Trim | Iconel 600 |

| Temperature Rating | -20°F to 500°F |

| Pressure Rating | 185 PSIG |

| Process Sealing | ANSI Class 5 Shutoff |

| Stem Sealing | PTFE Packing & 2 x Quad Seals |

| Connection Type | ASME 150# |

| Control Characteristics | Linear |

| Flow Direction | Bi-Directional |

| Dimensions | Any dimensions on this site or in literature are for reference only and not to be used for construction |