Aegis Flow Technologies

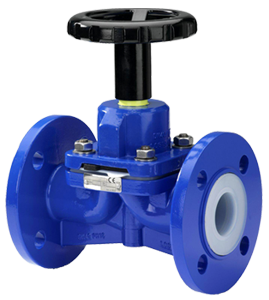

Fully Lined with Packless Design, Valves.

Fully Lined with Packless Design, Valves.

| LDV Valve | Product Specifications |

| Application | Isolaton and Control of Corrosive and Highly-Toxic Process Liquids and Gas |

| Standards | API 598 |

| Size | 1"-6" |

| Body Material | ASTM A395 DI |

| Trim | PFA Diaphragm |

| Temperature Rating | -22°F to 302°F |

| Pressure Rating | 235 PSIG |

| Process Sealing | Bubble Tight Shutoff and Zero Stem Leakage |

| Stem Sealing | Diaphragm |

| Connection Type | ASME 150# |

| Control Characteristics | Linear |

| Flow Direction | Bi-Directional |

| Dimensions | Any dimensions on this site or in literature are for reference only and not to be used for construction |